TRAYS

Advanced Trays for Efficient Distillation Processes

Trays are separation devices used in process plants, most often in distillation towers. The tray column is one the most widely used types of distillation columns.

Liquid flows down the column and across the trays after the liquid enters in crossflow or countercurrent flow. A reboiler located at the bottom of the tower separates the stream into a vapor that returns to the column as well as creates a liquid product stream. The vapor travels upward through the trays and makes contact with the down-flowing liquid stream.

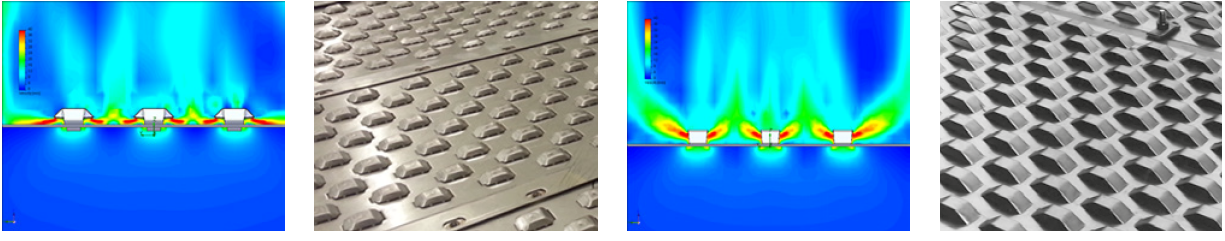

V-Grid trays

The V-Grid tray technology utilizes a fixed valve and combines the characteristics of sieve and float valve trays. main advantages are as follows.

High efficiency over a wide operating range through improved vapor-liquid contact.

Superior mechanical strength by increased stiffness of tray deck,

No moving parts and therefore no wear.

Smaller valves provide more capacity than larger ones due to re-duced pressure drop and entrainment rate. MVG trays provide higher capacity compared to standard sieve or valve trays, while providing higher efficiency and lower pres-sure drop per theoretical stage.

Sieve trays

Sieve trays find a wide acceptance as a low cost mass transfer device where high turn-down is not required. We offers all common sieve tray designs including small holes for improved vapor capacity and Venturi holes for low pressure drop.

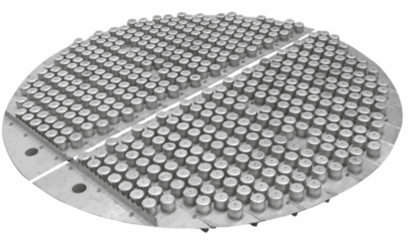

Bubble Cup trays

These trays are provided with inverted bubble caps having vertical slots fixed over cylindrical risers. Vapour travels upwards through the risers and diffuses through the bubble caps. These are generally used for low liquid loads & wide range of turndown ratio without weeping.