TECHNOLOGICAL UNITS

Custom Technological Units for Industrial Solutions

Besides own production of equipment we focus on activities in the supply of technological units. We delivery are own and foreign products that need to be supplemented by other facilities and services so that they can be passed on to the customer as fully functional technological units, including all relevant warranties and accompanying documentation. Although this field of activity originally developed in connection with supply of centrifuges, it has developed into other areas such as pumps, compressors, chemistry and pharmacy technologies,

Company SULTRADE:

- focuses on custom-oriented and bespoke delivery of technologies and special equipment

- is willing to make its own development and modification of key components

- is ready to deal with its own laboratory development of chemical technologies and subsequent deliveries of whole technological lines

- has experience in manufacturing our own equipment (eg industrial centrifuges) working in explosive or highly aggressive environments

- has experience based on broad international cooperation on the part of both suppliers and customers and is proven by successful cooperation with AGROFERT

SULPHURIC ACID NEUTRALIZATION WITH WHITE GYPSUM PRODUCTION

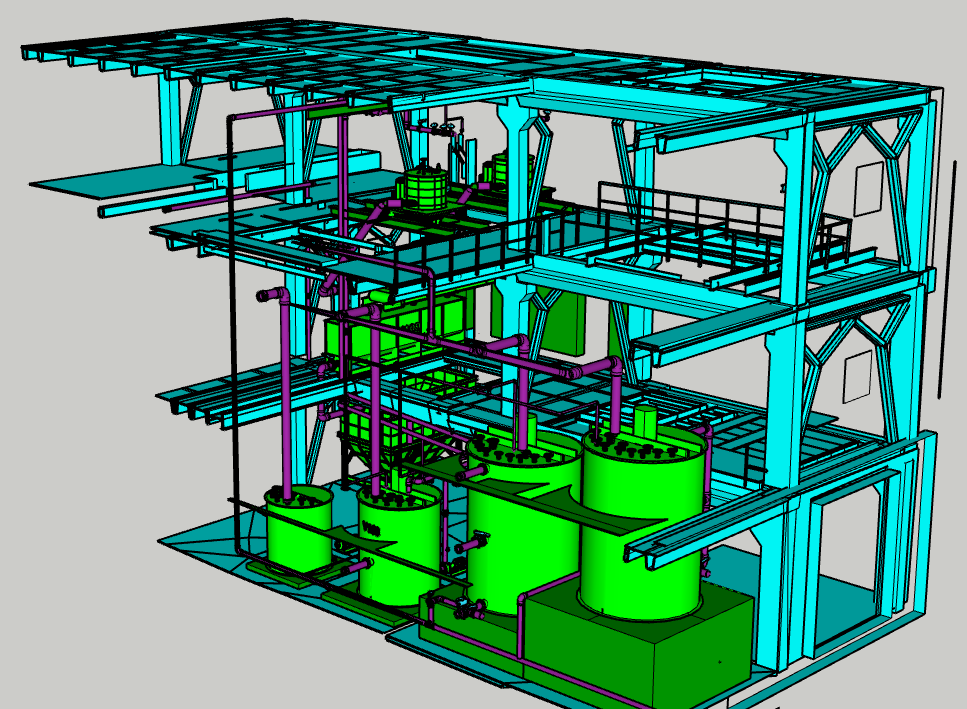

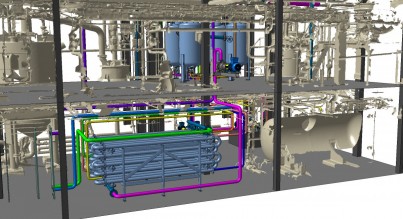

In 2019-2020, SULTRADE implemented a sulfuric acid neutralization project at the SOHIM plant in the Republic of Belarus. The project consisted of the complete construction and supply of turnkey technology for the neutralization of waste sulfuric acid to form chemical white gypsum. The specificity was that the client requested the placement of the technology in the existing building. First, a 3D scan and initial deployment of the apparatus was performed, then a project was developed, including pipeline isometries, where it was complicated to deal with collisions with the existing building and air conditioning, followed by delivery of tanks, pumps, fittings, instrumentation, SCVB 1000/630 GS centrifuges, including their installation. and supervision. The commissioning and successful fulfillment of the guarantee conditions for gypsum production was fulfilled in November 2020. The technological line is capable of neutralizing up to 7 m3 / h of sulfuric acid with the production of 1.8 t / h of gypsum with a quality of 13% residual moisture.

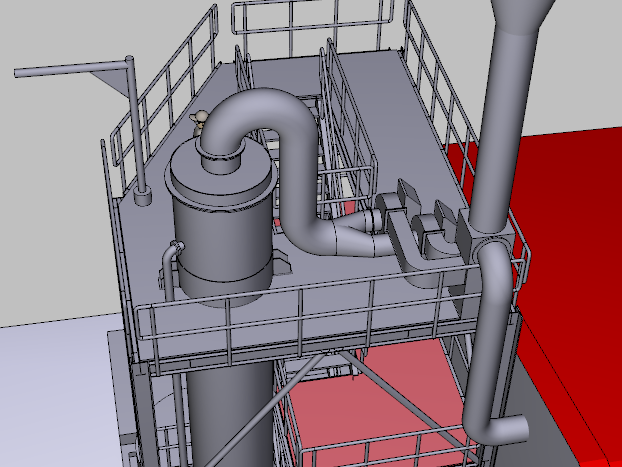

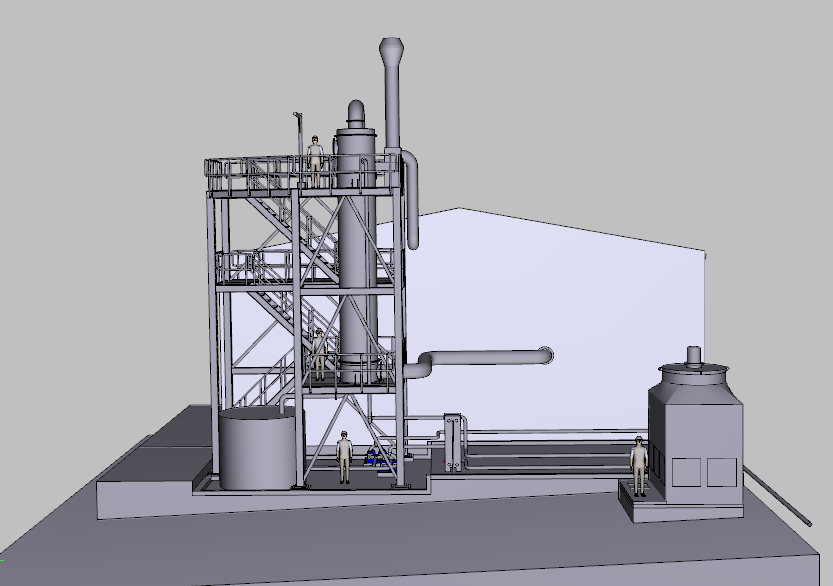

AMONIA SCRUBBING UNIT FROM WASTE WATER

In 2017 SULTRADE implemented the project and supply of turnkey technology for wastewater ammonia scrubbing. The unit capacity is 2.5 – 10 m3 / h of waste water with an ammonia concentration of 300-1600 mg / l. The unit operates on the principle of water vapor stripping after alkalization of waste water with NaOH. The stripping takes place under atmospheric pressure in a packed column (manufactured by Sulzer Chemmtech Ltd.)

The stripped product is waste water with an ammonia content of less than 50 ppm, which is further disposed to an existing wastewater treatment plant.

As a byproduct of stripping, ammonia water (a solution of 25% by weight NH3 in water) is removed, which is formed by condensation of vapors drawn from the head of a stripping column in a heat exchanger.

CHLORINE DISPOSAL UNIT

In 2017, SULTRADE processed a Chlorine Disposal Unit with a total capacity of 3,000 Nm3 / h of gas containing 3 t / h of chlorine, with an outlet chlorine concentration not exceeding 15 ppm vol.

COLUMN RECONSTRUCTION AND MODERNIZATION

2018 – Delivery of project documentation for the construction of a Project to increase the efficiency of the column.

2017 – Complete realization of the construction according to own project documentation. Replacement of the column internals, including the modifications of the steel constructions and piping connections.

2015 – Complete realization of the construction according to own project documentation. Replacement of the column internals including pipe connections, measurement of the temperature profile and installation of the chromatographs.

The column is fitted with internals manufactured by Sulzer Chemmtech Ltd.

EXCHANGES OF PUMP AND TURBINE INSTALLATIONS

We focuse on replacing of existing sets with new ones with an emphasis on optimizing the technical solution with regard to fitting new sets into existing technology.

We provide complete supplies, pumps and reversible pumps from renowned manufacturers (eg FLOWSERVE) as well as supplies of motors, couplings and foundation frames. We carry out assembly and piping assembly and assembly work by connecting MaC and Electro.

2017 – Replacement of pumps for supply of pyrolysis furnaces on EJ in UNIPETROL Litvínov, CZ

Replacement of four KSB pumps for new FLOWSERVE pumps including piping to fuel tank (flow rate 120 t / hour (GA-101) and 90 t / hour (GA112)

2016 – Replacement of two lines of the HALBERG (1500 m3 / hour) and high-pressure and low-pressure Francis turbine by J.M.VOITH (2000 m3 / h) with new pumps consisting of pump and SULZER reverse pumps, replacing flow regulation Francis turbine blades with FLOWSERVE control valves

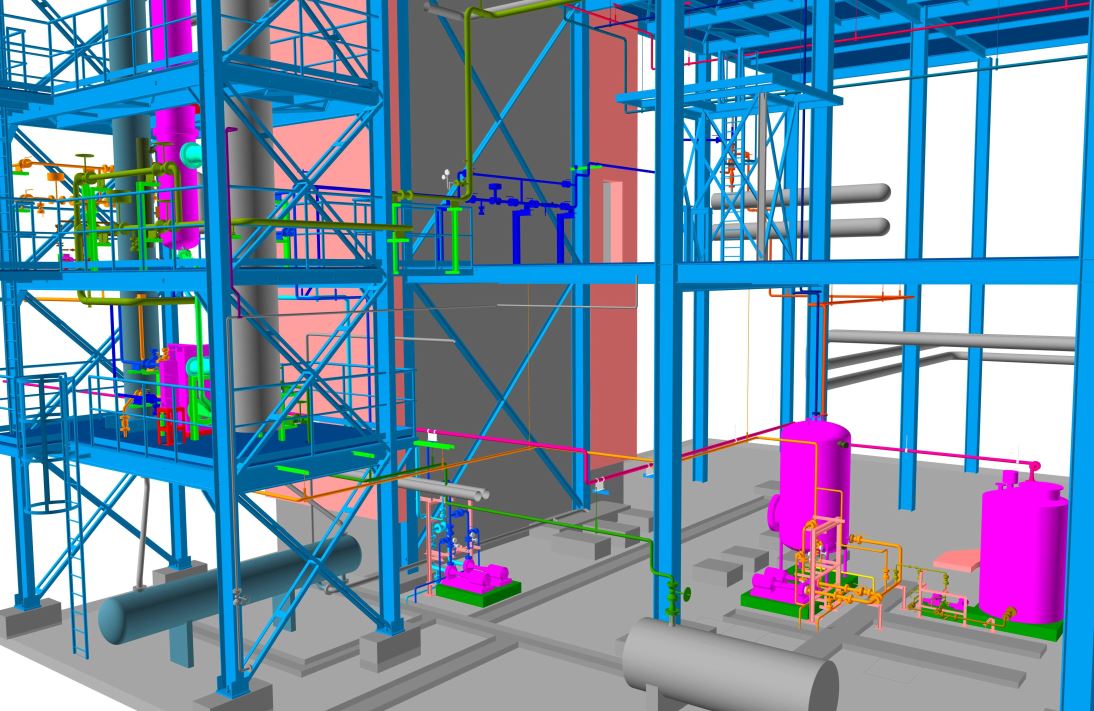

DEACIDIFICATION AND RESIDUARY ACID PROCESSING TECHNOLOGY FOR NITROCELLULOSE PRODUCTION

In 2012, SULTRADE supplied the Deacidification and Residuary Acid Processing Technology II for Synthesia. Supply including civil part and design based on 3D scanning.

In 2009 – 2011, SULTRADE supplied the Complete Acidification and Processing Technology for Synthesia. The subject-matter of the “turnkey” project was to provide individual apparatuses on the basis of basic engineering of the BOWAS company, preparation of all technical documents, installation and putting the process line into operation.

STUDY AND DEVELOPMENT OF TECHNOLOGIES – PRODUCTION of 2 ETHYL HEXYL NITRATE

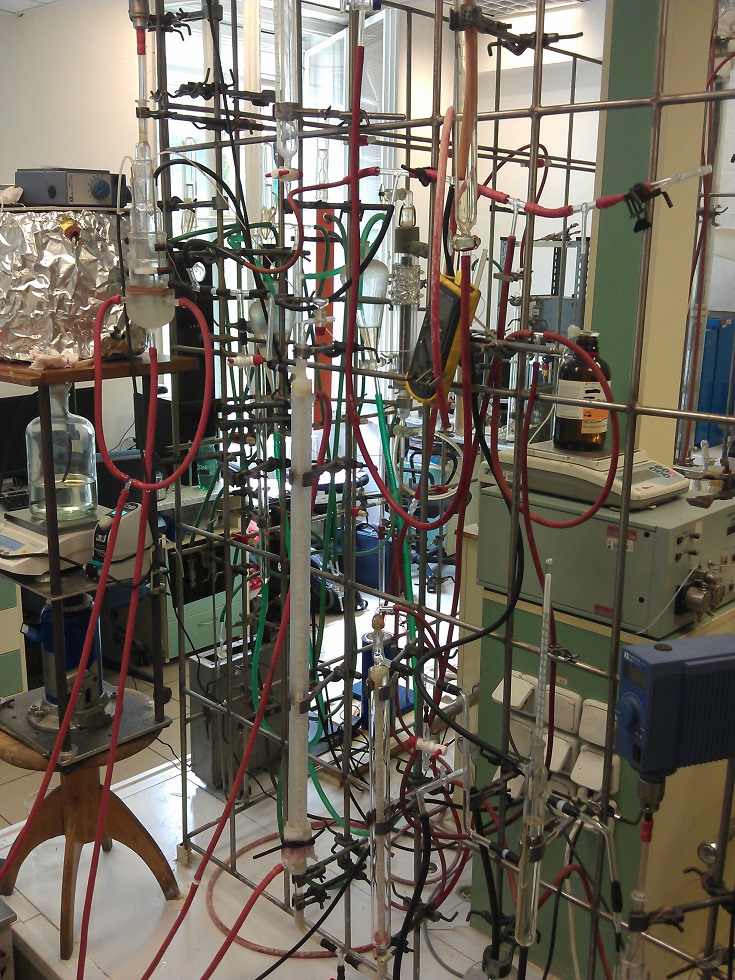

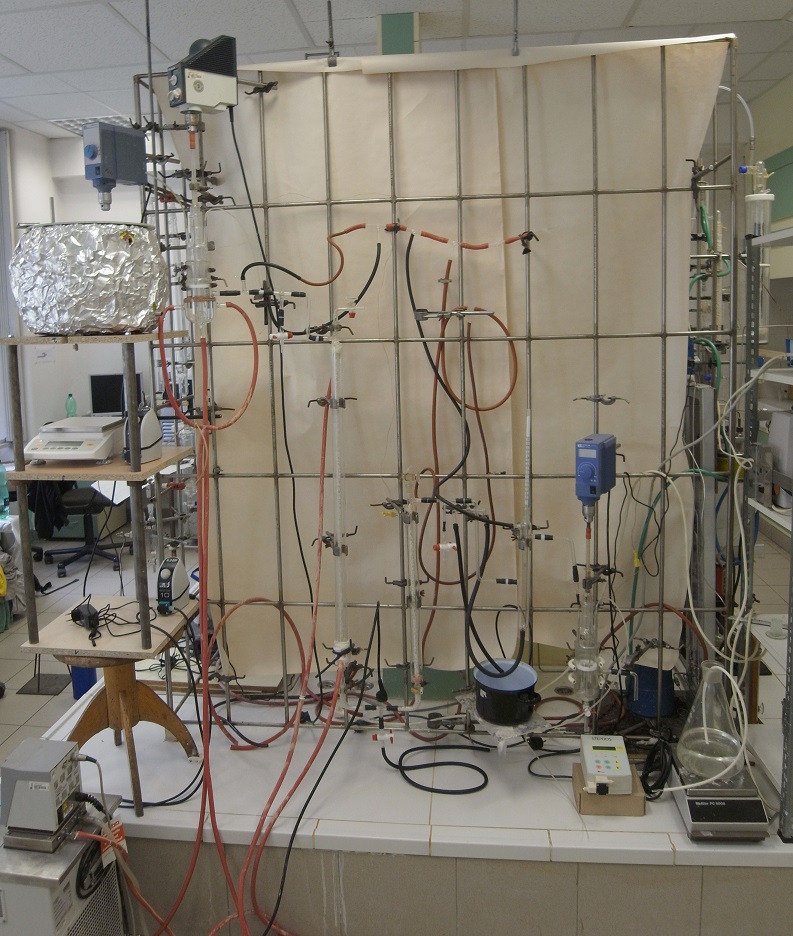

In 2012-14, SULTRADE, in cooperation with the Institute of Chemical Technology Prague, developed a study on the possibilities of production 2-ethylhexyl nitrate (2-EHN) so that the newly designed technology does not conflict with existing patents. 2EHN is one of the most used substances added to diesel fuel to increase the cetane number.

Based on this study, we designed a continuous laboratory unit to verify the functionality of the production. On the basis of the laboratory unit, SULTRADE designed a pilot plant for the new technology of production 2EHN with a capacity of 400t / year, with a view of the extension to about 10,000t / year, this technology has SULTRADE patented.