TOWER PACKING AND INTERNALS

Tower Packing and Internals for Distillation Columns

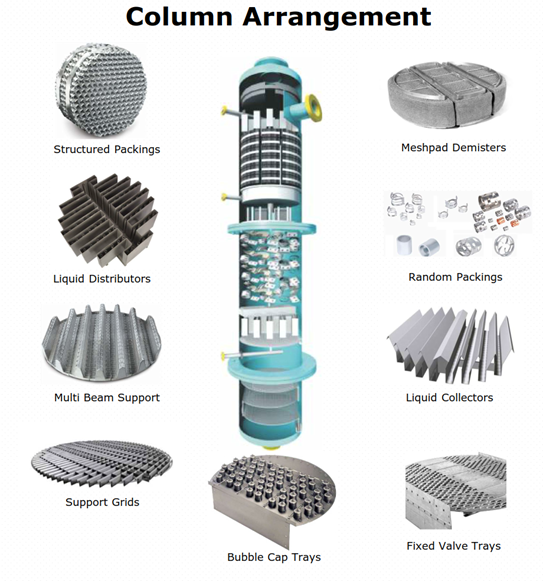

SULTRADE Praha has long experience in supplying the internal equipment for rectification and absorption columns. We offer a wide portfolio of products including structured or random packing, mass transfer trays and internal equipment for columns in the chemical, refinery and petrochemical industries.

It is based on a fact that the vapour of a boiling mixture will be richer in components that have a lower boiling point. The vapour phase is created by boiling of the liquid phase using steam or an electrical heating element. The more volatile component will distribute more in the vapour phase and the less volatile component will distribute more in the liquid phase. Based on this fact distillation columns can be designed according to the fractionation process.

Mass transfer compenents are used to distribute the liquid evenly and to increase the gas-liquid contact area.

There are different types of distillation columns each designed to perform specific type of separation. Here we classify distillation columns on their method of operation.

Batch Columns

In batch columns the feed is introduced in batches. Simply put the column is charged with a batch and the distillation process is carried out. On achieving the desired task the next batch of feed is introduced.

Continuous Columns

Continuous Columns process the feed continuously. No interruption occurs unless there is a problem with the column or the surrounding process units. They are capable of handling high throughputs.